Cy-laser’s fiber laser cutting system

Cy-laser manufactures and sales fiber laser cutting systems to cut sheet

and offers various solutions from compact layout suitable to solve factory space problems or for prototyping

to complex and customized systems. Such versatility represents a great strength for the company

which foresees two main structures: the Airplane structure and the Gantry one.

Fiber laser cutting system

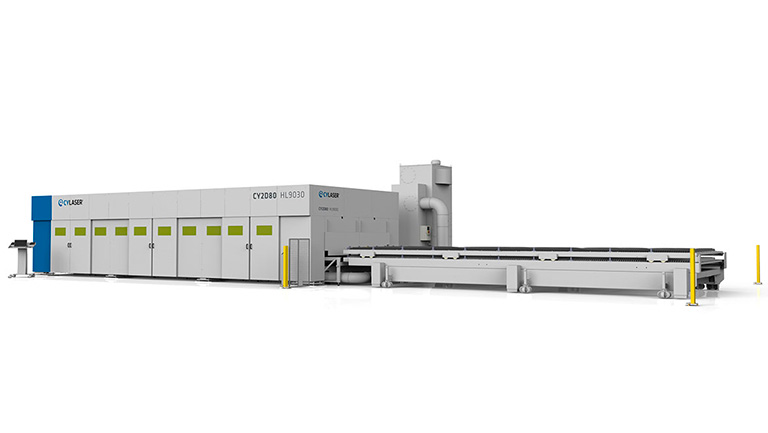

the airplane structure

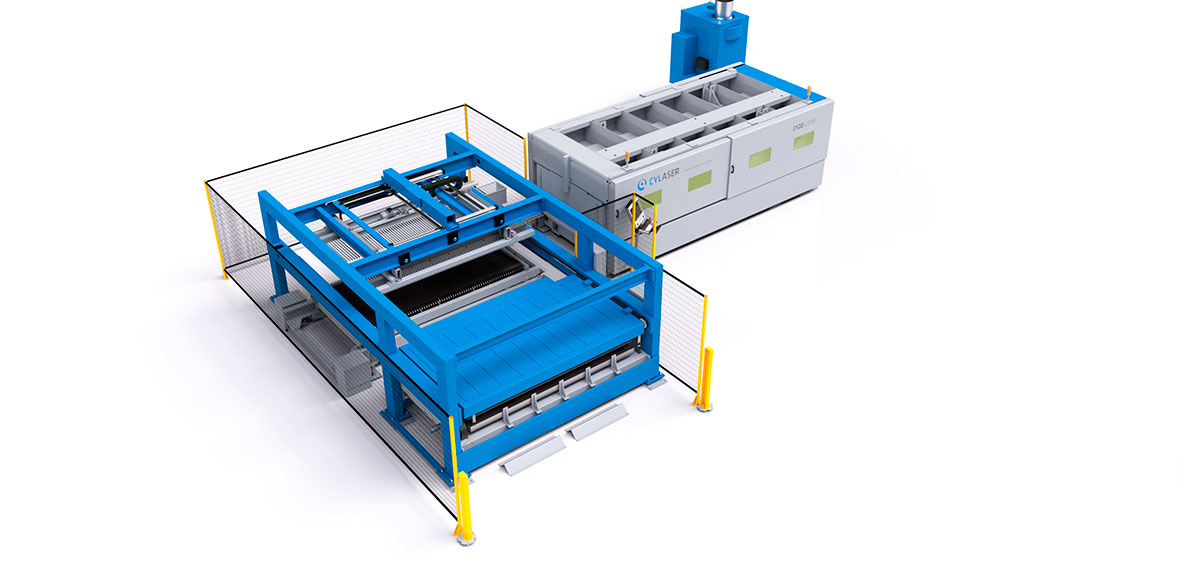

This version is ideal for big formats. Thanks to its great mechanical stability, it grants very high precision level. It is possible to retrofit a higher power generator without making substantial modifications; the motion parts are placed in the upper part of the machine and as such they are protected from dust and scraps generated by cutting and then collected in a dedicated scrap box. The structure features a total and bilateral access to the working table thanks to its sliding doors and it could be combined by a vertical storage tower to process multiple sheets on a single pallet. It is available in the Long version with loading station on one side of the machine and the Side version with loading station in front.

Fiber laser cutting system

the gantry structure

The Gantry structure is highly performing and precise in its movements thanks to the lowered center of gravity and, based on the model, it has front or side access to ease the ordinary operations. It is a dynamic structure that can be equipped with linear motors (the fastest in the range thanks to the 4g acceleration), or rack and pinion for an extremely high precision. The portal architecture is a guarantee of a major rigidity and it allows to maintain max precision even with the high acceleration of the axes given with the use of the linear motors. The structure is greatly sized as evidence by the 14,000 kgs weight and it features integrated tables which allow to lower the center of gravity to increase its dynamics. They are equipped with suction drawers over the entire length of the machine and they work in sections that activate and disactivate depending on the position of the cutting head in the working area.

Cy-laser’s fiber laser cutting system

features

All Cy-laser machines apply to a constructive philosophy with use of OTS components which are available and compatible with main CAD-CAM software in the worldwide market; there are multiple configuration possible in order to meet customer’s production needs. The majority are interfaceable with loading and unloading automation which can be placed left or right to optimize the production flow. The dimensions of working benches go from 3000 x 1500mm to 13000 x 3000mm. Following is the complete list of the Cy-laser cutting systems.

Cy-laser proprietary cutting head

The proprietary cutting head is one of the key components of the laser machine and it has been designed and developed internally since 2005. It is a mature and consolidated product, highly appreciated in the market thanks to the continuous improvements and exclusive process options; it combines lightness and structural rigidity which grants a precise production even with high dynamics. Further to the standard version, the cutting head is available for inclined cuts more known as bevel cuts, a special 5 axis cutting head with variable chamfer and a dedicated one for high power generators.

Cy-laser’s automation

for its fiber laser cutting systems

Cy-laser offers customized automations which make the various working processes faster,

reliable and more efficient; they allow a totally unmanned production for a continuous productivity.

Cy-laser systems can be integrated with different automation; from a simple loading and unloading station up to a fully automatic storage tower. The Compact Server Side distinguishes for the possibility to load sheets from the side or front in total autonomy. The choice depends on the position where the automation is placed and on the processing flow that one wants to give inside the company.

The Compact Server Side and the Compact Server Long have same function with the second having the extra advantage to be removeable from the working bench and making the machine in a stand-alone version.

One of the peculiarities of these solutions is represented by the de-sheeting of sheets which function consists in a combination of systems that separate the sheets and an electronic system that verifies the correct withdrawal.

For those companies that have the need to stock and manage different thicknesses and materials, Cy-laser offers its Compact Store. The tower can be customized both by determining the number of cassettes based on the height of the factory or by determining the number of loading and unloading cassettes are needed. Based on the working program, the Compact Store activates a specific cassette and through a process similar to the Compact Server, manages the sheet which once processed will be found in a precise position of the storage tower.

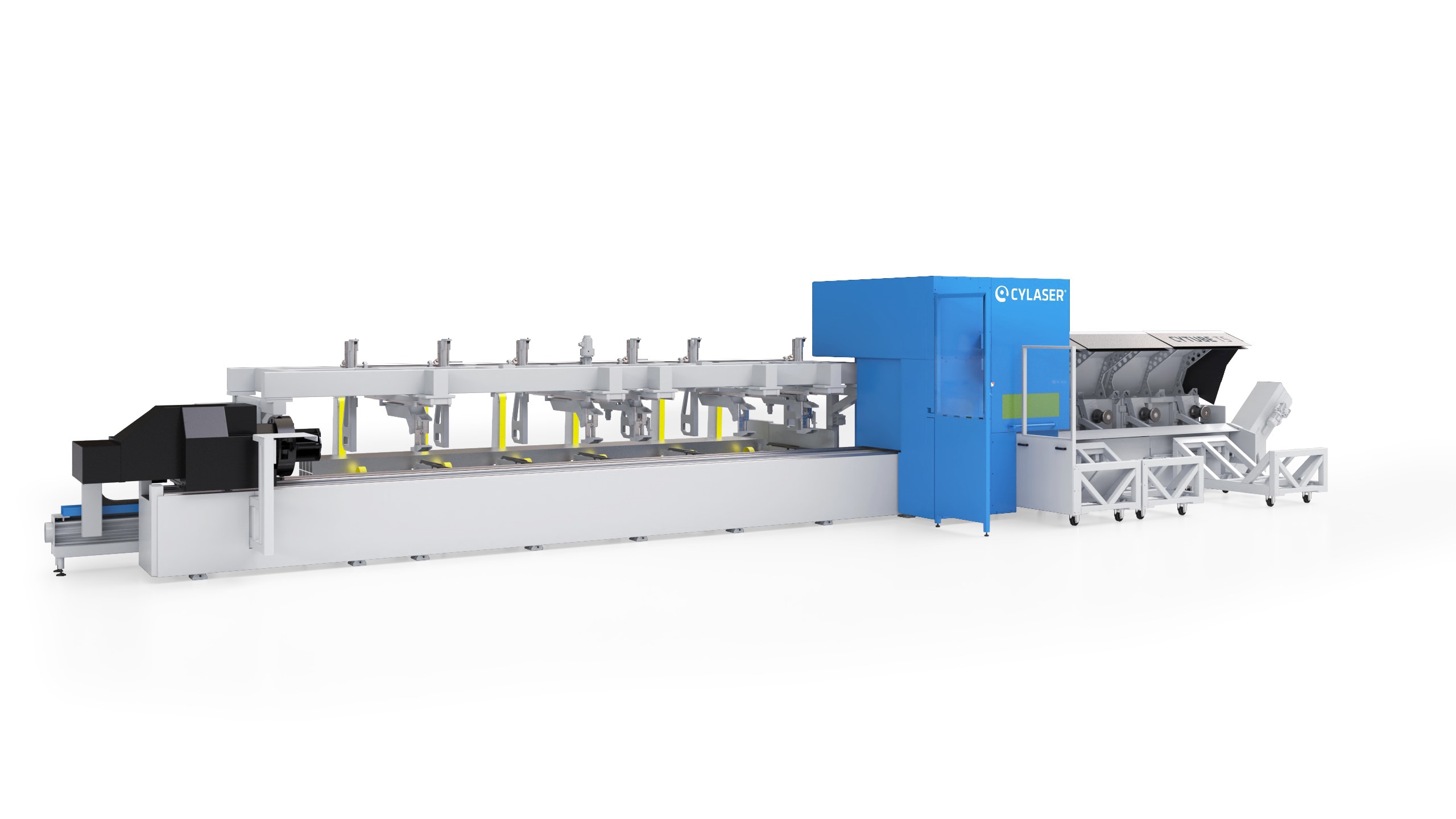

CYTUBE:

cy-laser’s solution for tube cutting

For tube cutting, Cy-laser offers its CYT5 and CYT9 models, two systems designed to cut tubes having different profiles (round, rectangular, square and more) with minimum diameter of 15 mm to max 225 mm and to manage loads from 20 to 40 kg/m. Compared to cutting systems of other manufacturers, both models are highly automated with management of 23 axes which make them economically competitive both in initial investment.

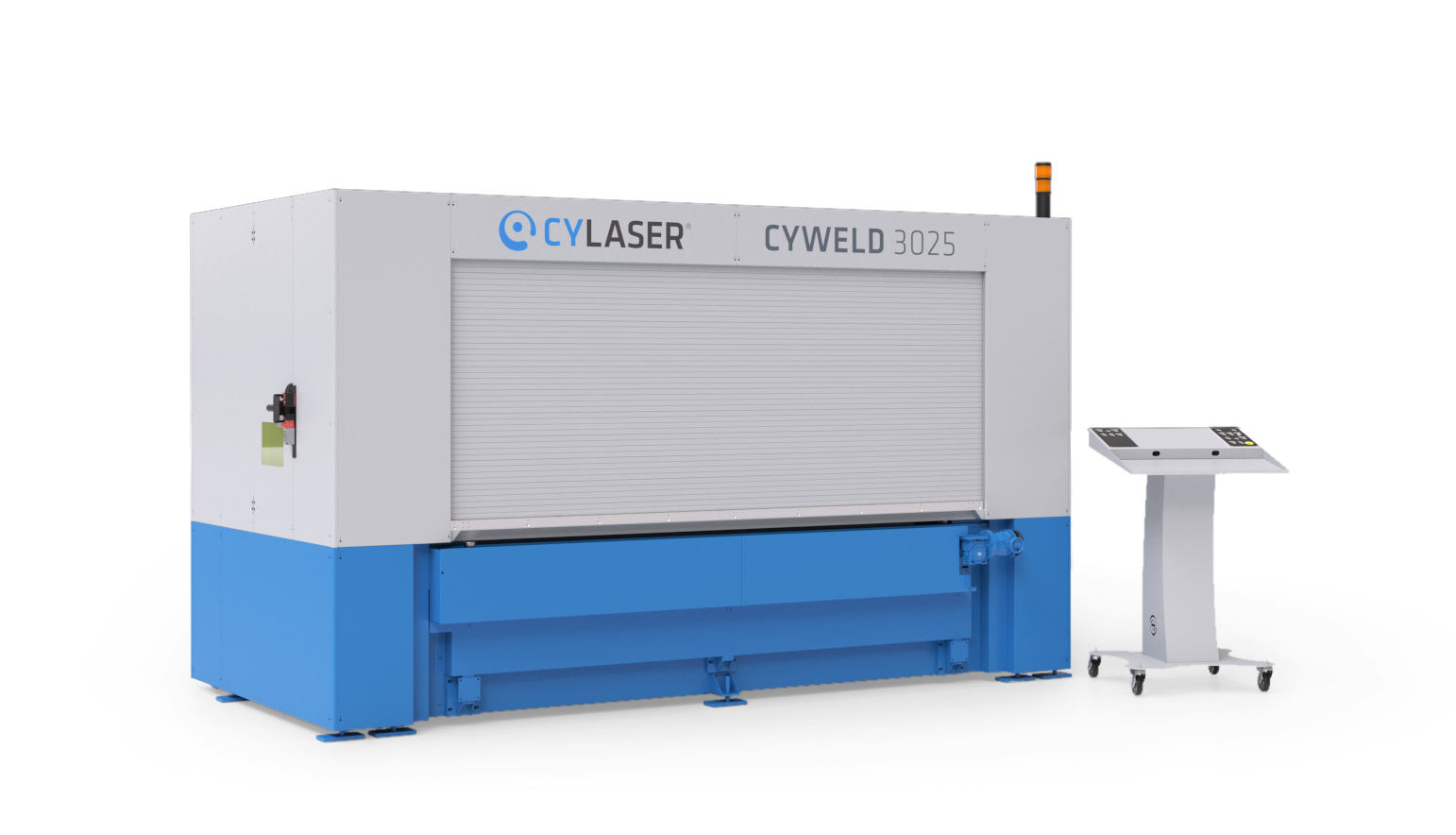

CYWELD:

Cy-laser’s welding system

For the laser welding, Cy-laser offers its CYWELD to weld two overlapped sheets and produce plates for the thermal exchange.