G.M.C. LAMIERE: the value of people and innovation

The story of G.M.C. Lamiere boasts fifty years of experience and three generations, all present in the company today. It’s the story of Umberto and Caterina Dall’aglio and their strong passion for steel, handed down to their three children Gunther, Monica and Cristina, and to their grandchildren Eric and Michela.

G.M.C. Lamiere manufactures semi-finished products for earthmoving and agricultural machinery, pharmaceutical sector, aesthetic components for exteriors, such as plates, gates, grids and gratings. It’s a company that invests in innovation and that operates successfully thanks to a united and motivated work team, constantly trained to be interchangeable and maintain flexibility in order to differentiate itself and become more competitive, with a high-quality production.

«The purchase of the new Cy-laser laser cutting system means for G.M.C. Lamiere a faster production and an ease of management and use, together with all the advantages of fiber laser technology, such as low consumption. The fiber laser has contributed to the growth of the company and opportunities but, together with innovation, it’s essential to bear in mind that people should always remain at the centre. Their ability to welcome new opportunities and face new challenges with enthusiasm is for me and my wife – says Umberto Dall’Aglio – the real treasure of a company. That’s what we strongly believe in and have always tried to hand down to our children, our grandchildren and employees during so many years of work and that we still find satisfaction in».

Precision even in large dimensions sheets

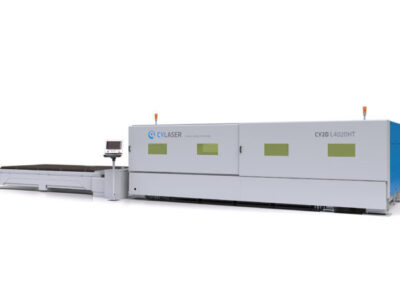

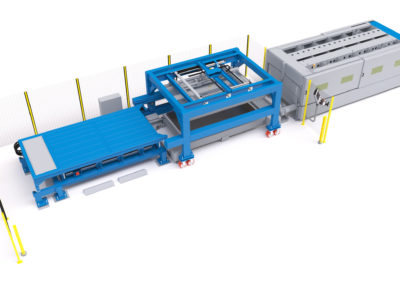

The Cy-laser CY2D HL4020 fiber laser cutting system realized for G.M.C. Lamiere has a working area of 4000×2000 mm, is ideal for cutting large plates with maximum precision and equipped with Compact Server Long loading and unloading automation. The airplane structure guarantees mechanical stability. The 6kW power generator and the Cy-laser EVO III cutting head allow the company to cut all sheet thicknesses normally processed. Thanks to the automation, it is possible to change production very quickly. By pushing a button, you just need to decide for the automation or a stand-alone process configuration.