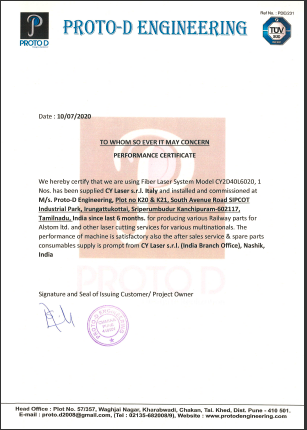

We completed the installation of a large format Cy-laser fiber laser system in Chennai (South India), last February, just before the lockdown. The machine is a 6 x 2 mt table machine, equipped with a 4.0kW fiber laser generator.

Proto-D Engineering, (company founded in 2008 and having its HQ based in Pune) has chosen to add to their existing large range of laser machines, a new machine that would combine the large format capability with very low operation cost.

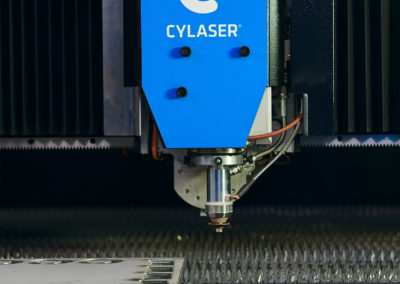

This is possible thanks to the unique Cy-laser motion system design (the so called “Airplane” structure) which, for its constructive concept, grants stability and high precision for the entire lifetime of the machine. It features an overhead X and Y axes assembly that does not run on the floor or the table itself as all other machines. The compactness deriving from said configuration delivers a stiff Y axis that is not subject to the flexion typical of a standard 6 mt gantry machine, hence delivering rapid motion speeds comparable to those of a small laser machine.

The motion system is positioned over a heavy-duty dual table, servo-motor pallet changer system, supported and actuated by 4 hydraulic cylinders.

Among other impressive features of the Cy-laser cutting machine, is the unique and very simple cutting head EVO. EVO III and EVO V HP (specific for high powers) are products of Cy-laser, both design and build, that have been refined for over 16 years when the company pioneered the application of fiber laser to metal cutting. These cutting heads have virtually NO moving parts, requires NO maintenance, with the exception of the slick break-away torch. It is only in the torch that a handful of consumables (protection screen, heat shield, nozzles etc.) are present, and easily accessible by the user. The Cy-laser cutting heads boast the longest focus lens lifetime in respect to the market’s standards thanks also to the High Back Reflection Safety system. Cy-laser does not require any head change after so many hours of operation. Coupled with their strong warranty (entire machine), they become a rather bullet-proof system. The cutting heads are designed to cut light gauge as well as plate up to 25 mm without focus lens changes.

Proto-D Engineering has been supplying components for various industry segments, including proto type, auto components, railways aerospace, energy, public infrastructure etc.